Movable shelving with soft touch electric drive

Electrically driven mobile shelving systems

|

|

Functions

A movable rack system provides a transmission option using an electric motor and gears connected to the transmission shaft. The control system has the following functions:

- opening,

- blocking,

- closing,

- alarm,

- exposure to ventilation,

- user protection, security

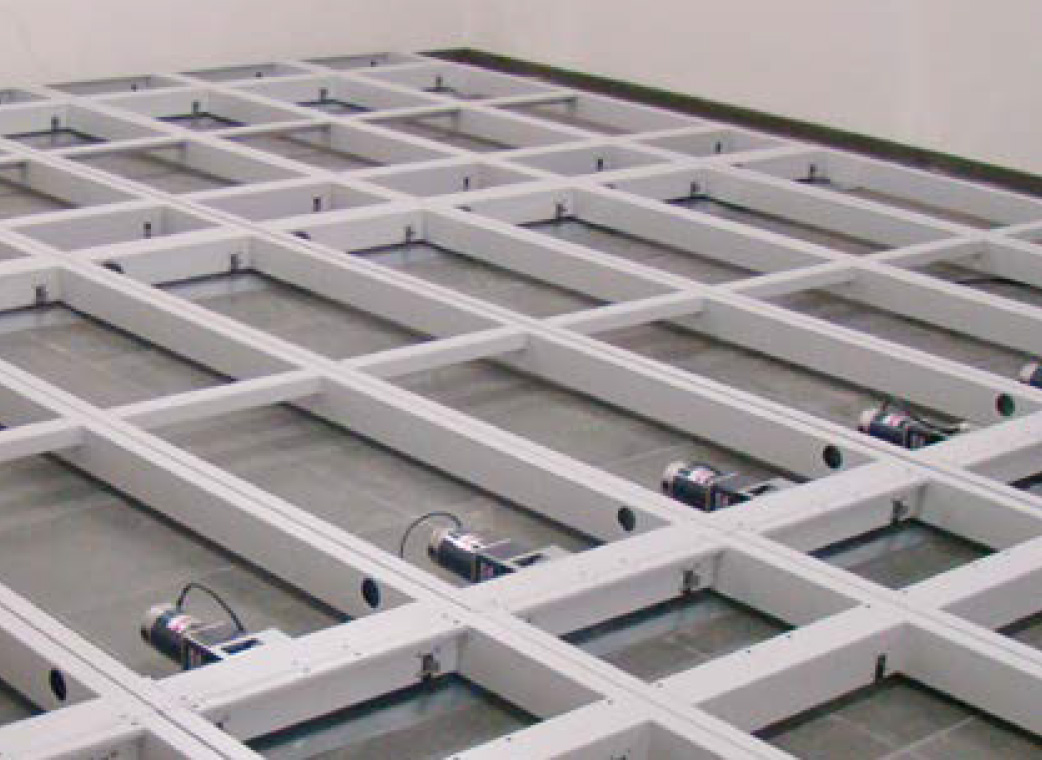

Rails for moving shelves

|

Mobile shelving systems have galvanized rails with a height of 12 mm. The rails are attached to the floor The track is anchored to the floor with screws. The transfer chains have an anti-tilt system that prevents tipping over. An optimally selected number of rails ensures smooth and easy movement of units. |

Metal frame

|

The frame is made of steel profiles, powder-coated in RAL 7035 color. The frame is equipped with spindles and cast iron wheels. The wheels have ball bearings to improve the quality of use. The frames are equipped with rubber distance buffers to prevent the blocks from slipping. Movable racks provide a transmission option using an electric motor and gears connected to the transmission shaft. |

Shelf-bearing walls

|

The load-bearing wall is made of powder-coated steel, perforated every 25 mm. Thus, the shelves can be adjusted to any desired height. Transverse fasteners are used for additional rigidity of the units. |

Shelves and side panels

|

The shelves are made of steel and are equipped with dividers that prevent documents from moving to other shelves. The load capacity of the shelves is 40 kg or 80 kg (optional). The front load-bearing wall from the side of the control panel is covered with a decorative panel. There is space for nameplates across the entire width of the panel. |

Security

|

The shelves are designed with the ability to block their movement with special keys. Access to specific units can be restricted to employees with a specific key. The shelves have a built-in night positioning option. All units move to ensure equal distance between them, as well as provide additional ventilation for stored items. The equipment is equipped with electric overload protection, which reacts to any obstacles during movement. Also, the racks are equipped with a passive safety system that allows users to view the open aisle before it closes. |

Control panel

|

The system is moved through the control panel located on the front wall of each unit. It is also possible to move all units with one control unit. The control panel allows you to indicate the direction of movement and the opening of the passage. Opening and closing a specific unit is done by simply pressing a button on the control panel. The panel is equipped with a system of signal diodes, which informs about a system failure. Additional control software has also been created for determining the location and type of emergency and signaling.

|

Accessories for mobile shelving systems

|

The lighting is electronically controlled and operates only above the device currently in use by staff. The light turns on automatically when the passage is opened and turns off when it is closed, and the software allows the user to set the time after which the light turns off. |

|

Grid panel system for safe storage of paintings. |

|

Pull-out frame-type drawers facilitate access to documents. |

Specification of mobile shelving systems

| Height |

2019 mm |

2394 |

|

| Shelf width | 1000 mm | 750 | |

| Shelf depth | 300 mm | ||

| Number of shelves in the section | 5, 6 or 7 shelves + 1 upper shelf as a dust cover | ||

| The space between the shelves | 350 mm | ||

| Height adjustment option | Every 25 mm |

||

| Shelf capacity | 40 kg | 80 kg (on request) | |

| Movement mechanism | Electric | ||

Additional equipment |

Shelf partitions/separators; Lock/locking mechanism for the handle; Pull-out drawer and frame (only for 370 mm deep shelves); Retractable/extendable shelves; Wire mesh for frames, paintings, etc. for hanging or installing wardrobe shelves. |

||

Office shelves with Soft Touch electric drive system

Technical specification of office mobile shelves

| Height | 1500 | ||

| With | 1000 | 1500 | 2000 |

| Depth | 600 | 800 | |

| Improved construction | The surface is covered with 16 mm thick MDF board with veneered edges, the shelf body is made of 0.6-0.8 mm thick steel sheet, the cabinet doors are made of 16 mm thick MDF board and 0.8 mm thick steel sheet, the front walls are made of 1.0 mm thick steel sheets, the front and back elements of the shelves are padded. | ||

| Improved assembly | ~725mm wide cabinets with louvered doors, equipped with ~300mm and ~400mm deep metal shelves, mountable on both sides, clothes hanger, ~300mm and ~400mm deep cabinets with MDF or metal doors, mountable sections on both sides, compartment for file boxes , shelves adjustable every 25mm, ~450mm high padded seat | ||

| Relocation | Electric drive, the power unit is placed on the rail, the sections can be moved at any distance, the drive transmission uses a low-power electric motor and gears connected to the drive shaft. | ||

| Electrical supply | The rack installation is powered by 230 V AC/16A, all control and drive elements are powered by max. 24V DC voltage. | ||

| Management | Skārienvadības panelis, kas novietots uz katras sekcijas priekšējās sienas, vadāms ar pogām, kas norāda sekciju kustības virzienu un koridora atvēršanu, papildu plauktu vadības programma, lai noteiktu un signalizētu bojājuma vietu un veidu. | ||

| Control panel functions | - opening, - locking, - reset, - failure indication, - dispersion, - ventilation, - worker protection, - safety | ||

| Rail | Galvanized rails bolted to the floor. | ||

| Safety | System overload detection function, - shelf stop function at 30 kg resistance - overload system (electrical), reacts to an increase in current in the electrical circuit when encountering an obstacle between sections. | ||

| Other functions | Night positioning function, which allows you to turn the shelves for ventilation at a certain time. | ||